Sieving cloths

According to the industrial standards of your specifications

Characteristics of sieving cloths and tension sheets:

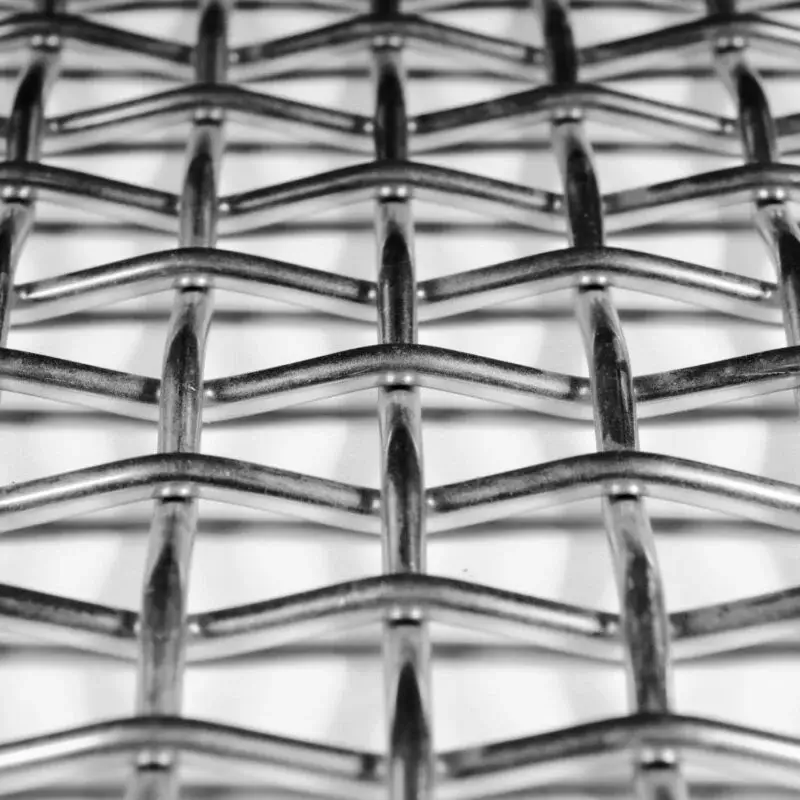

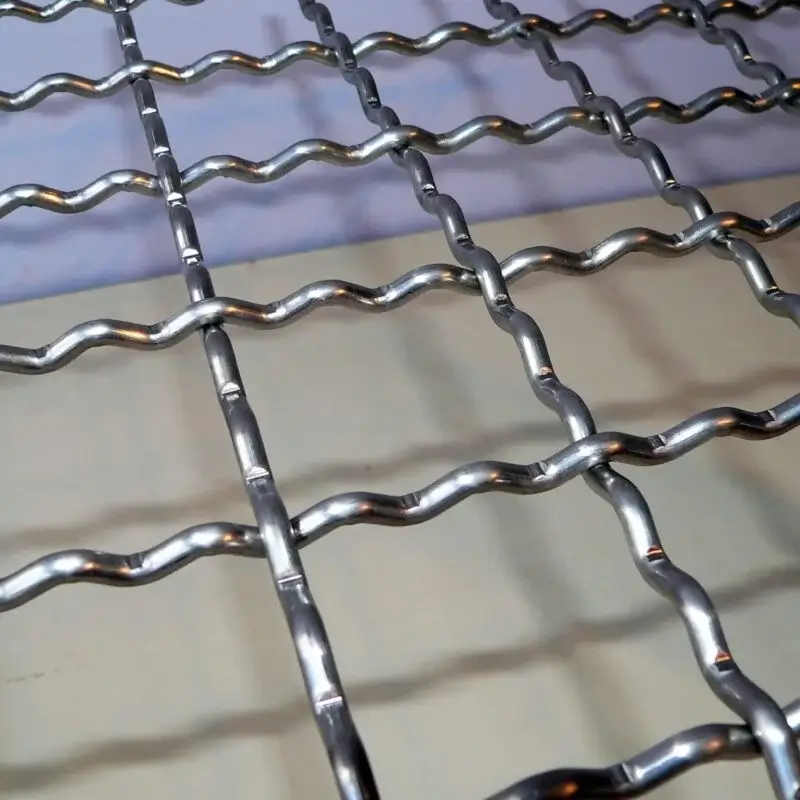

- A variety of designs available, such as harp sieves and screen decks with long or square mesh sizes, both welded and woven.

- Custom Solutions: Adaptable to the unique requirements of various applications.

- Robustness and Corrosion Resistance make them ideal for heavy industrial sectors.

- Advanced production techniques such as weaving and welding of metal mesh ensure versatility and efficiency in particle size separation.

- Reliable in harsh conditions and adaptable to specific machines.

Applicability:

- Important in sectors such as recycling, sand, gravel, and soil processing.

- Suitable for a wide range of industrial applications due to the variability in sizes and thicknesses.

Materials:

- Manufactured from various materials such as spring steel, manganese steel, and stainless steel.

- Use of additional materials such as plastics for specific industrial requirements.

- Strong and durable, designed to meet the demands of demanding industrial environments.

Sieve Technique

Sieving is a method where particles of material are mechanically separated based on size. This process occurs on the sieve deck of a sieving machine, where materials are separated by allowing them to flow over a sieve surface that may or may not allow them to pass through.

The material is discharged onto the sieve decks and moves across the surface through vibrations. These vibrations are caused by an eccentric shaft or a vibrating motor that activates the sieve box. These vibrations play a crucial role; they must be powerful enough to push the materials across the sieve surface and remove any particles stuck in the sieve openings.

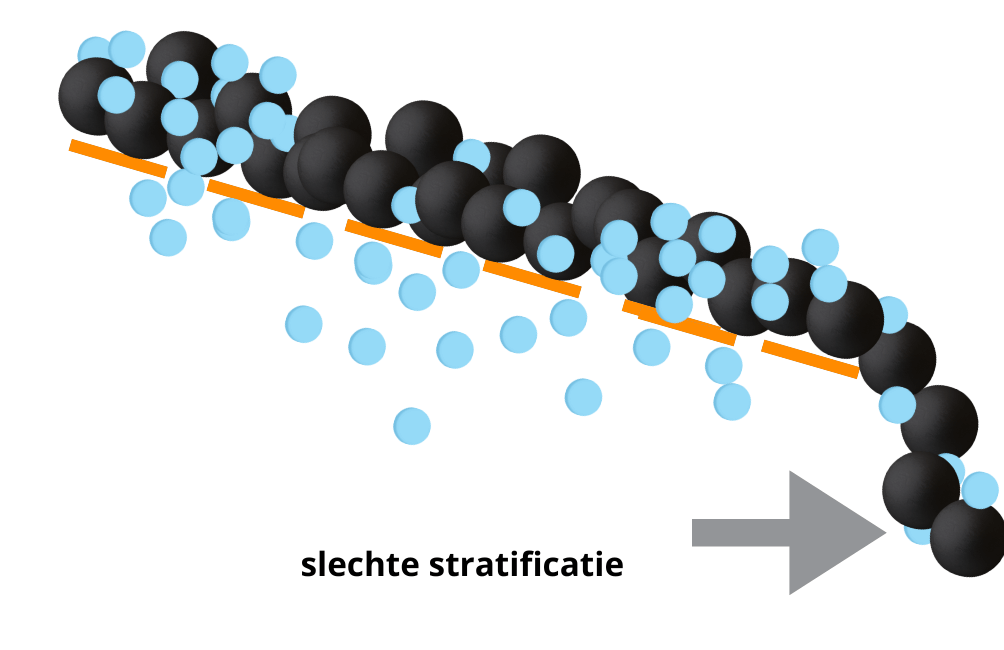

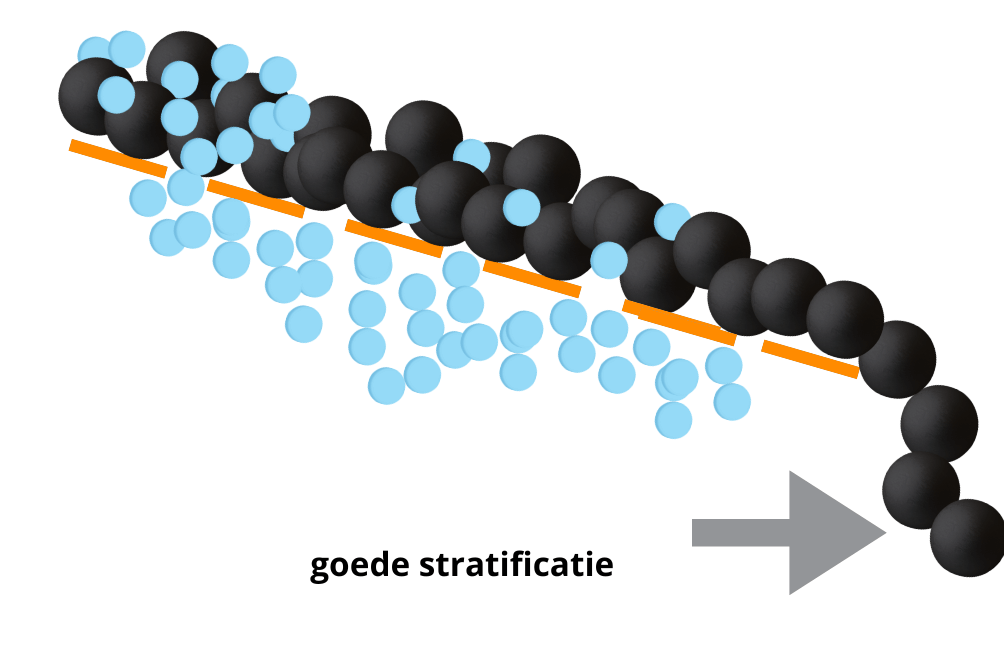

The efficiency of these vibrations depends on various factors such as the volume and mass of the material, the inclination of the sieve surface, and the stickiness of the particles. Effective vibrations result in stratification where larger particles come to the top, and finer particles move further through the sieve surface.

The efficiency of the sieving process is measured by the percentage of smaller particles that successfully pass through the openings of the sieve deck. Choosing the right sieve deck is essential for optimal sieving results.

Sieve Mesh

When choosing sieve mesh, the type of material, wire thickness, and the size of the openings are especially important. These choices greatly influence how the mesh performs.

Thinner wire typically means more open space in the mesh, allowing more to pass through and thus enabling the sieving machine to process more. However, be mindful that thinner wire can also mean the mesh wears out faster.

Therefore, it’s important to carefully consider which sieve mesh best suits your needs.

Do you want advice on which mesh is best for your sieve deck? We’re here to assist you with personalized advice to make the right choice.

Didn't find what you were looking for?

return to our overview of industrial filters

More info? Give us a call! +32 (0)9 228 17 95