Crimped wire mesh

A solution for filtration, shielding and protection

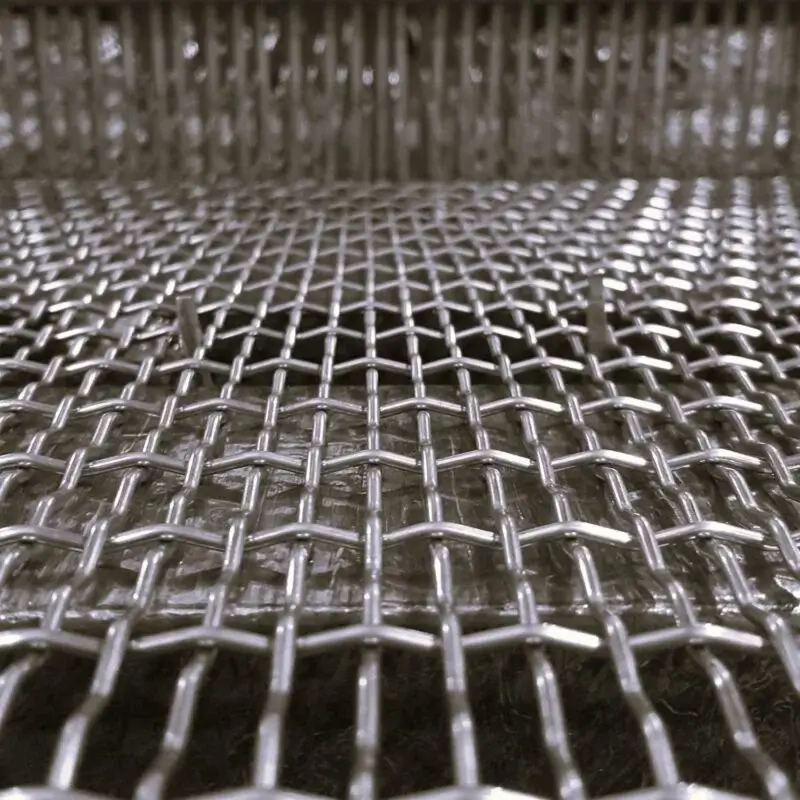

Crimped wire mesh is manufactured using a technique where the wires are pre-crimped. At the crimps, the wires are tightly interlocked, resulting in a mesh with exceptional strength and stability. Its durability and ability to retain shape even after impact make it a cost-effective and long-lasting solution.

Characteristics:

A rigid mesh supplied as standard in panel form. On request, it can also be produced in rolls.

The mesh is not easily deformable or bendable (unless significant force is deliberately applied).

These panels require heavy-duty cutting shears or a grinding disc for processing.

Rigidity is maintained through the tension between the interlocked wires. This means they ALWAYS have protruding wire ends — trimming these ends would release the tension of the outer wire and reduce structural integrity.

Available in various mesh openings and wire thicknesses.

Materials:

Stainless steel: Valued for its durability and corrosion resistance.

Aluminium: Lightweight and often used for decorative applications.

Brass and steel: Offer distinct aesthetic and mechanical properties.

Galvanized steel: Provides extra rust protection compared to plain steel.

High-grade stainless materials: Such as Inox 304L, 316L, and 310, each chosen for specific properties like heat resistance or suitability for food industry applications.

Applications:

Fencing and filtration: Used for sieving, protection, and security purposes.

Decoration: Applied in both interior and exterior architectural designs.

Construction industry: Used for façade cladding, balcony and balustrade infill, and as reinforcement in concrete structures.

Interior architecture: Integrated into exhibition stands, lockers, and suspension systems.

Agricultural sector: Applied for machine guards and partitions in barns.

Green landscaping: Serves as plant support, greenery façades, or fall protection over ponds.

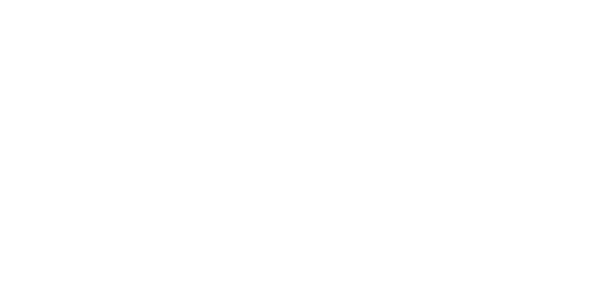

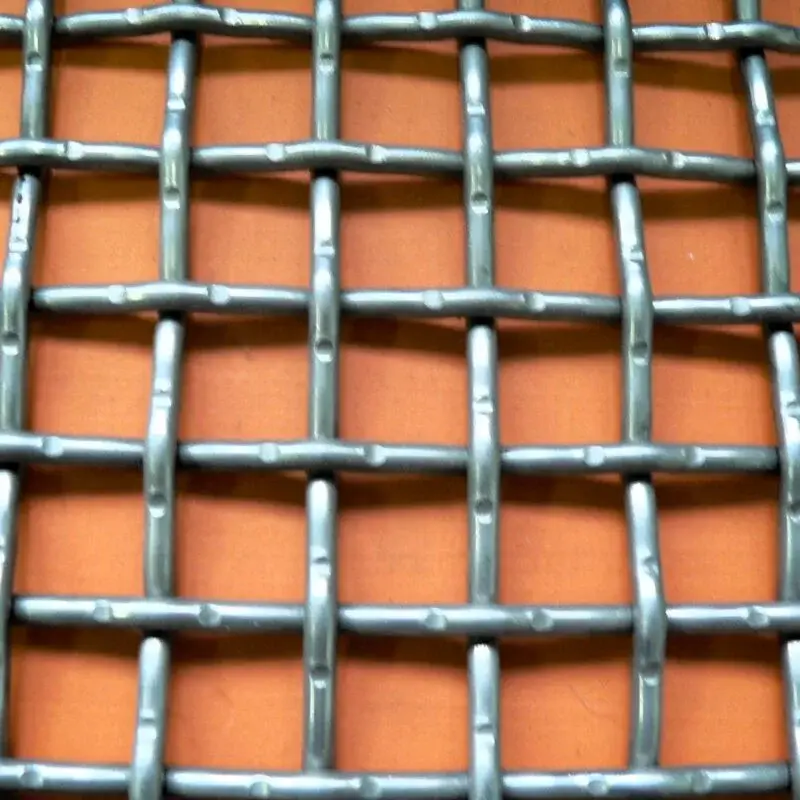

Plain Crimped Wire Mesh

The notch given to the wire beforehand has an upward and downward cap. Once woven together, there is no flat side.

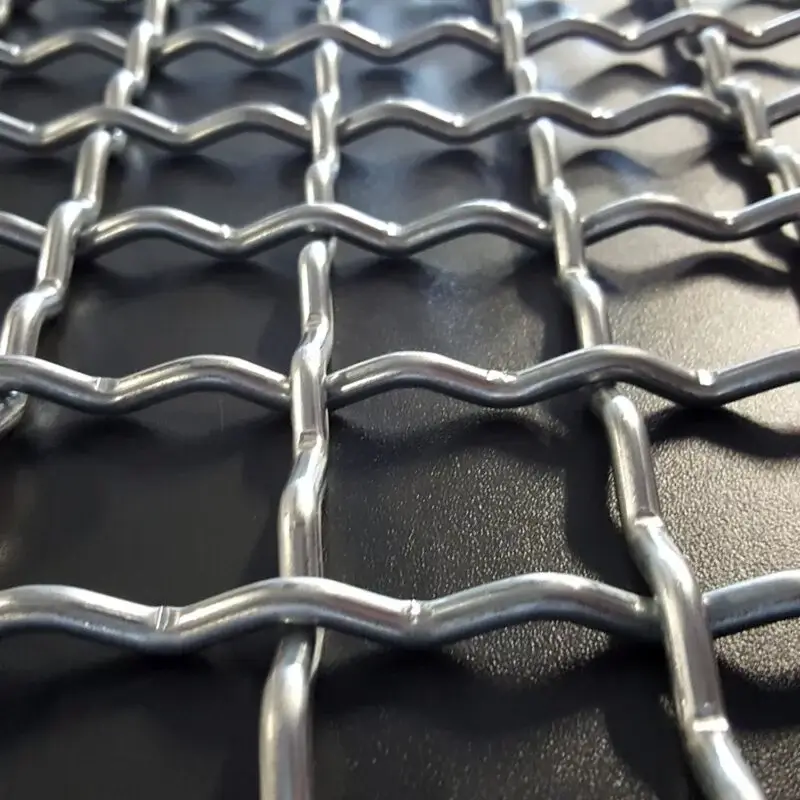

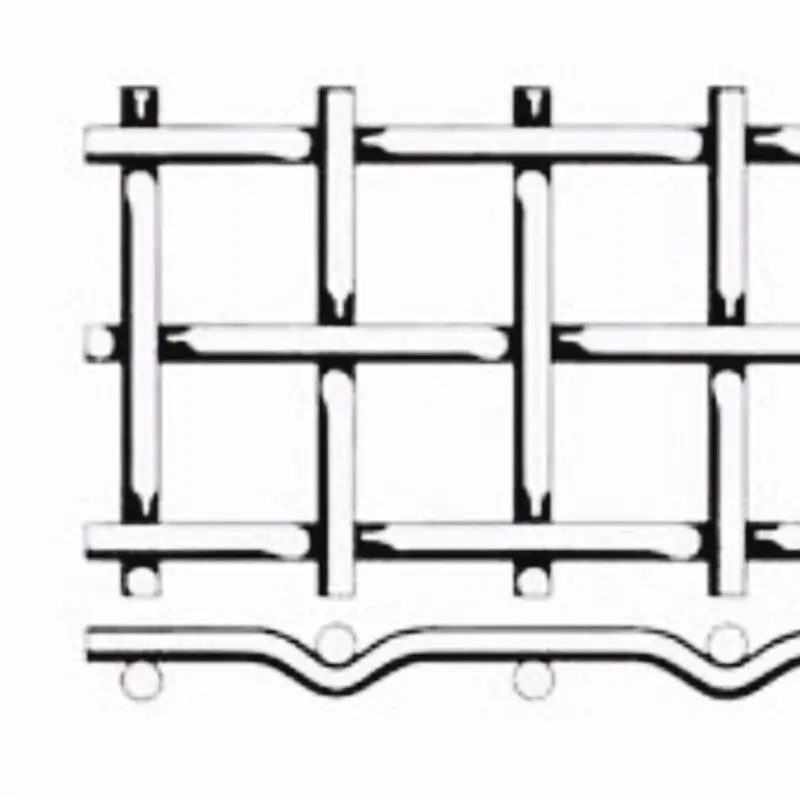

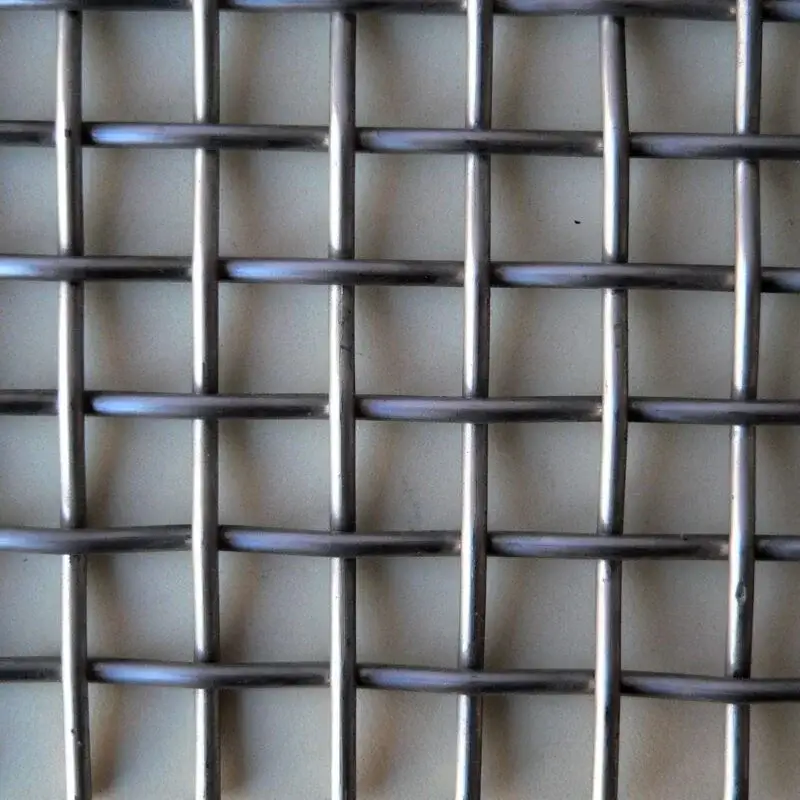

Single Crimped Wire Mesh

The pre-applied notches in the wires are shallower and less complex. Once woven, the result resembles woven metal mesh but with the distinction that both the grille and the wires are stiff and strong. Unlike woven sieve mesh, which is usually more flexible and rollable with smaller mesh openings.

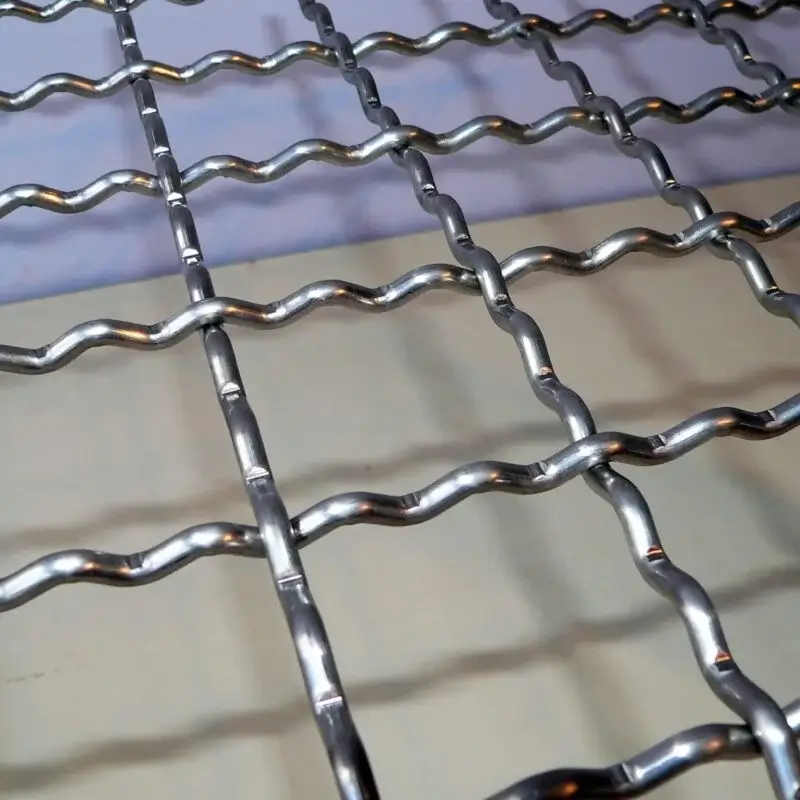

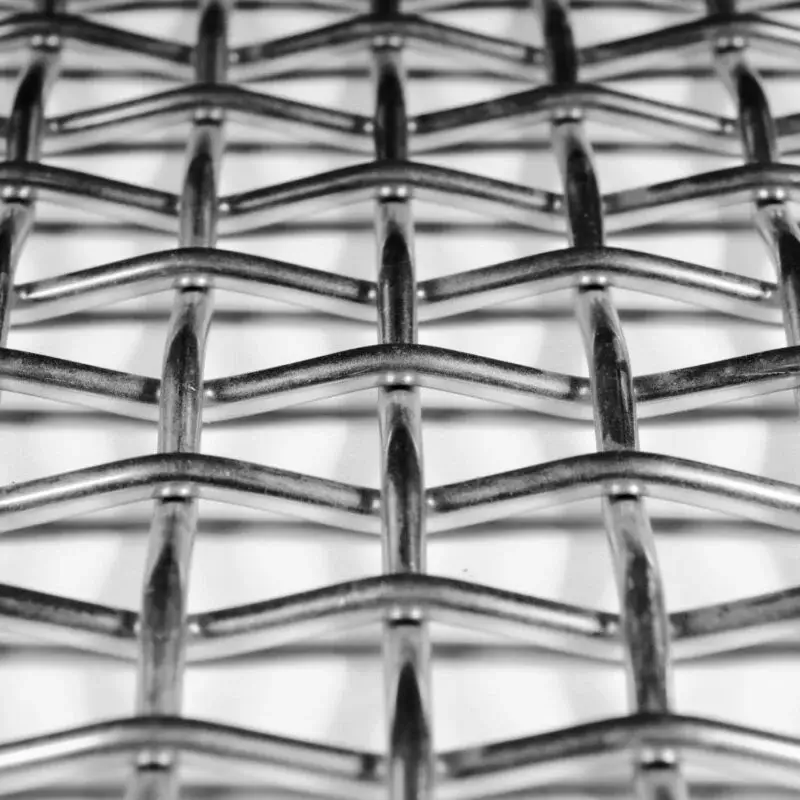

Lock Crimped Wire Mesh

The notch applied to the wires beforehand is always on the same side. Once woven together, the grille has a flat side. The advantage of this is that the surface is smoother on the flat side.

Didn’t find what you were looking for?

Return to our overview of Metal filter mesh and grates.

More info? Give us a call! +32 (0)9 228 17 95