Professional screen garnissage and re-garnissage for industrial screens

- In-house production of screen mesh and large material stock

- Correct screen tension and precise filtration fineness

- Technical advice tailored to your screening process

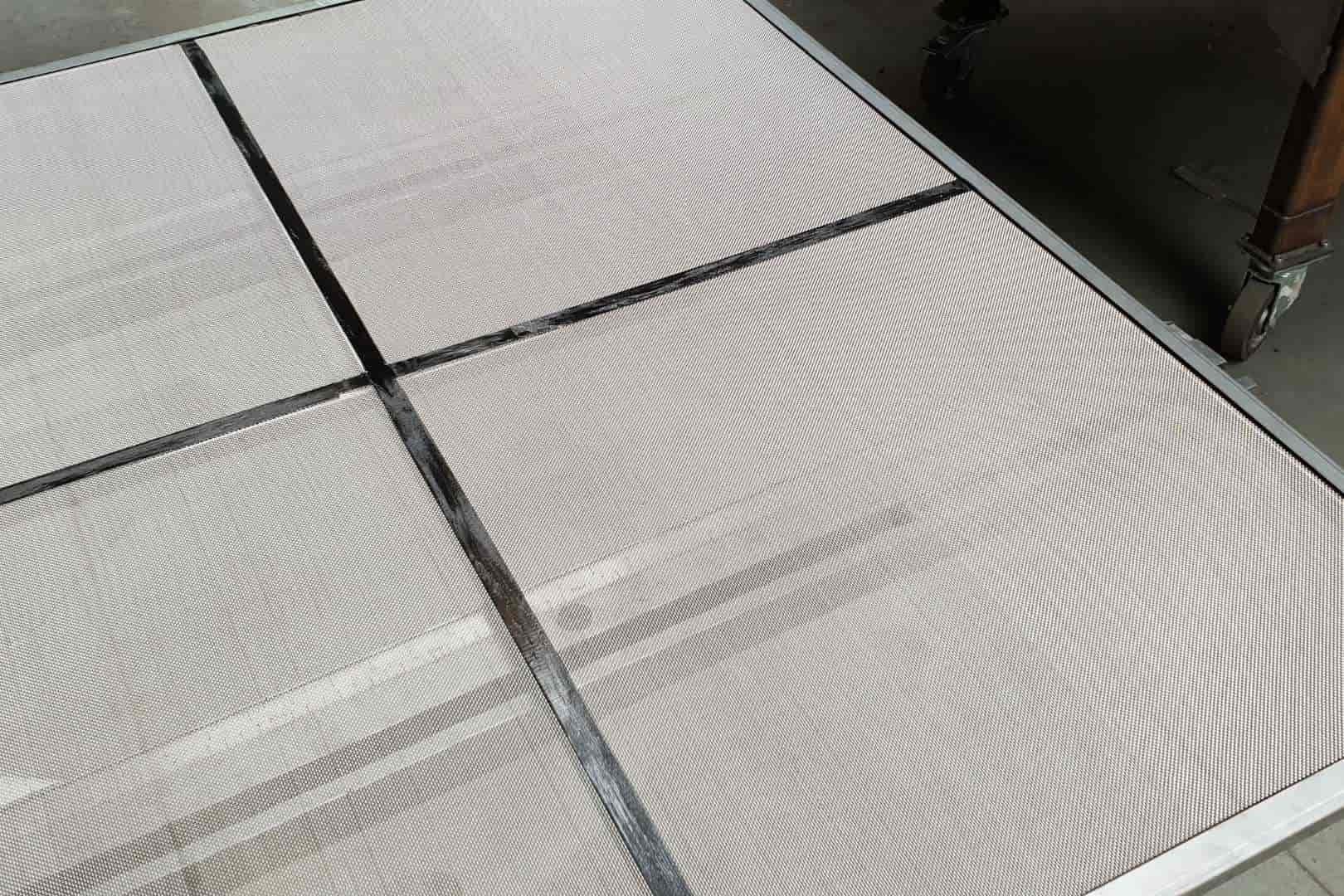

Re-garnissage of a screen frame is the professional replacement of worn or damaged screen mesh on an existing screen frame or screen ring. The frame itself is retained, while the mesh is completely renewed. This makes re-garnissage a cost-efficient, sustainable, and technically sound solution for industrial screening and filtration applications.

At Omnimesh, we specialize in technically correct screen garnissage for industrial filtration and separation processes. We focus on uniform tension across the entire screening surface, the correct filtration fineness, and reliable operation within your process, minimizing downtime, product loss, and quality deviations.

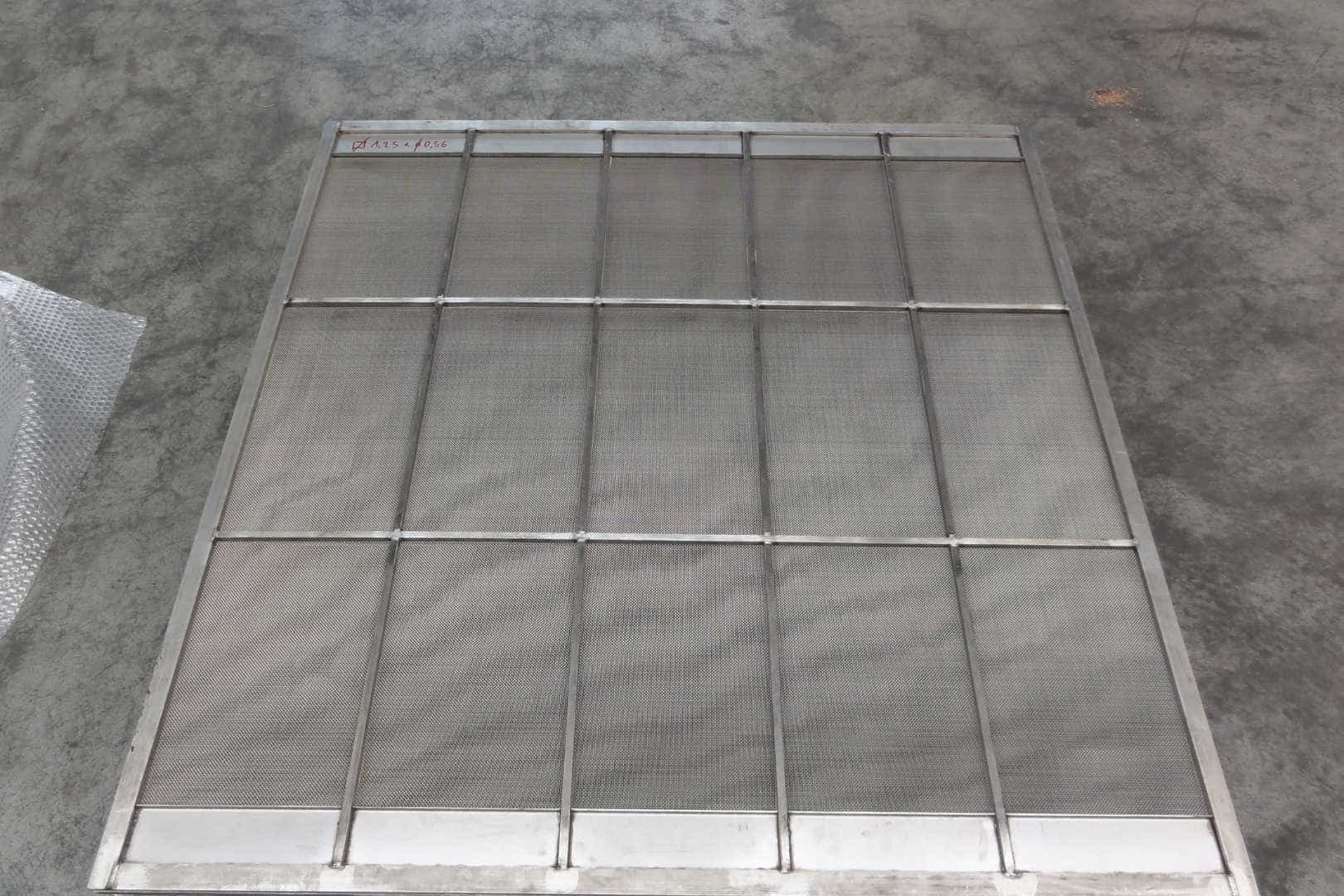

Which screens and screen decks do we garnissage and re-garnissage?

Omnimesh has the technical expertise, experience, and infrastructure to technically correctly garnissage and re-garnissage all common industrial screens, regardless of brand, type, or age of the installation, with diameters up to 3000 mm.

Common applications:

→ Screen decks for vibrating screens

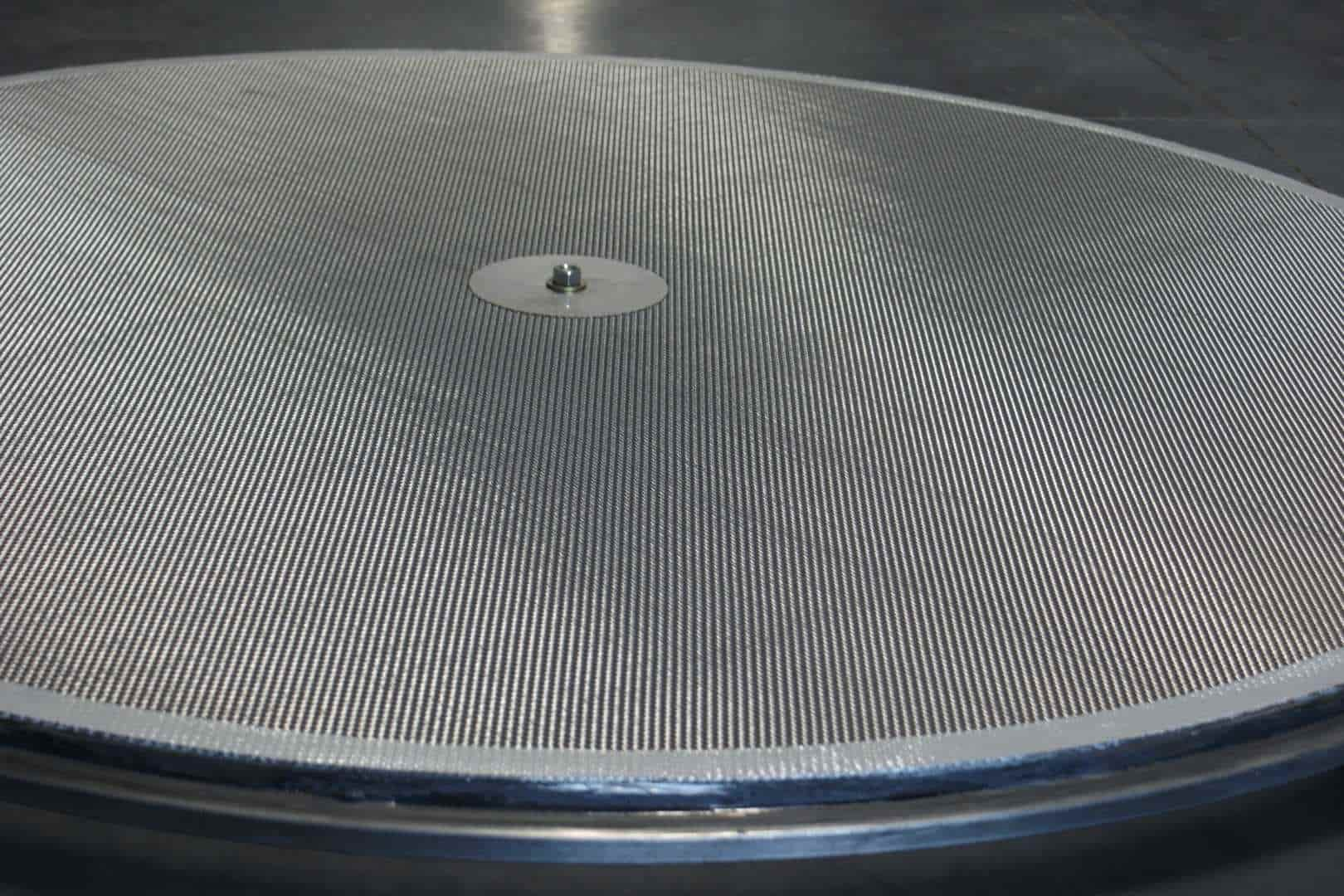

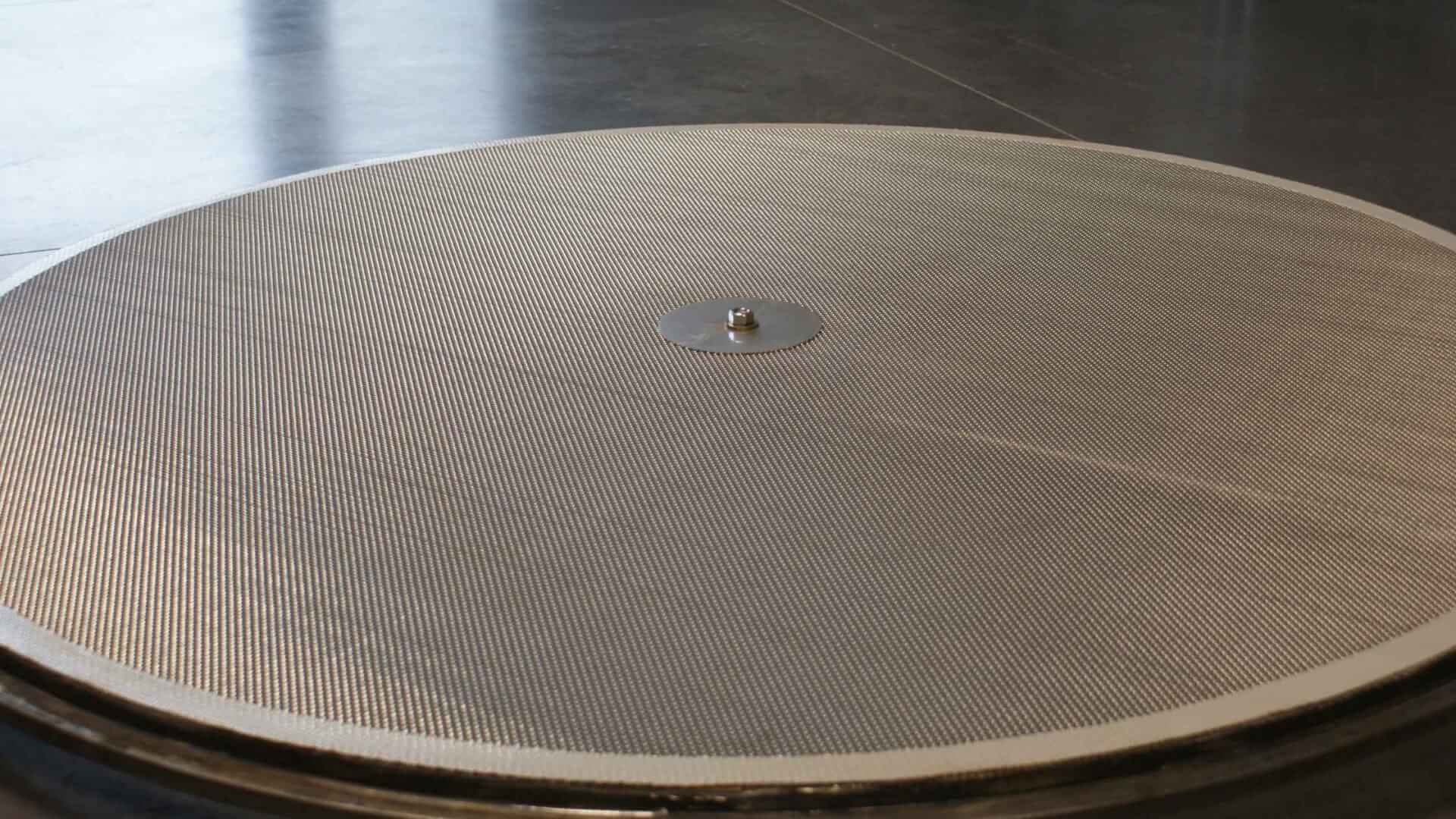

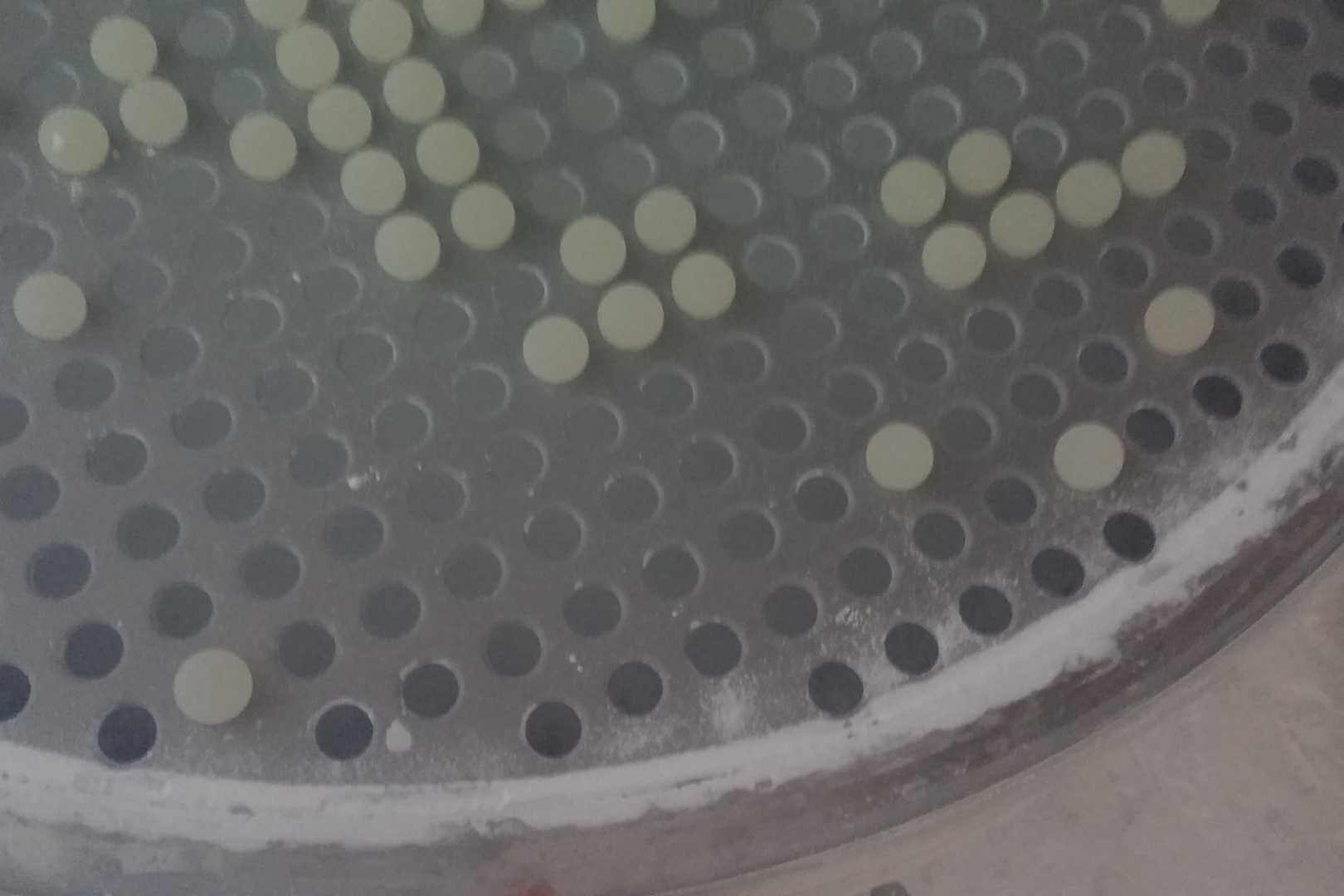

→ Screen rings and round screens

→ Oscillating screens and flat screens

→ Ultrasonic screens

→ Screen frames for process and production separation

Repair of industrial metal filter elements

Not every filter or screen issue can be solved by re-garnissage alone.

When the filter frame is damaged, the element is structurally deformed, or when corrosion, weld failures, or complex wear are present, screen garnissage alone is insufficient.

In such cases, Omnimesh offers a complete repair service for industrial metal filter elements, focused on making your filter sustainably and reliably reusable within the production process.

Our garnissage service focuses on precise assembly, uniform tension, and reliable operation within your process.

When do we (re-)garnish a screen ring or screen frame?

Re-garnissage of a screen frame is the process whereby:

the existing screen frame is retained

the worn or damaged mesh is removed

new mesh (metal, plastic, or nylon) is accurately and tightly applied

The goal is to restore or improve the performance of the screen without replacing the entire frame.

A correctly re-garnished screen frame ensures:

uniform tension across the entire screening surface

consistent throughput and separation quality

stable operation during vibrating or oscillating motion

Which problems can we solve with screen (re-)garnissage?

Industrial screens are continuously exposed to mechanical stress, vibration, wear, and contamination. This often leads to reduced screening quality or production losses.

We address, among others, the following problems:

→ Torn or damaged screen mesh

→ Uneven or lost screen tension

→ Wear of the screen mesh caused by abrasive products

→ Clogging or contamination of the screening surface

→ Insufficient separation quality of the filter mesh

→ Outdated or incorrect filtration fineness

→ Adjusted screening specifications due to process changes

How does the (re-)garnissage process of an industrial screen frame or screen ring take place?

Our professional re-garnissage of screen frames and screen rings is carried out according to a fixed, technically controlled procedure. This allows us to guarantee consistent screening quality, uniform tension, and long service life, even under intensive industrial use.

Step-by-step re-garnissage of screen frames and screen rings

- Removal of the existing screen mesh

Worn, damaged, or contaminated mesh (plastic, nylon, or metal) is completely removed without damaging the frame. - Thorough cleaning and technical inspection of the frame

The screen frame or screen ring is cleaned and inspected for deformation, weld cracks, wear, or corrosion. - Selection and precise alignment of new screen mesh

The correct mesh type and mesh size are selected and precisely aligned to ensure optimal throughput and separation. - Accurate tensioning with controlled tension

The new mesh is evenly tensioned to prevent tension differences, sagging, or premature wear. - Bonding and edge sealing for durable fixation

Industrial bonding and sealing techniques ensure a strong, vibration-resistant anchoring of the mesh. - Final inspection of tension, stability, and functionality

Each re-garnished screen frame is inspected for tension, mechanical stability, and operational reliability.

This re-garnissage process for industrial screens delivers a reliable, reproducible, and cost-efficient result, ideal for applications in filtration, separation, screening processes, and screen printing, where downtime and quality loss must be kept to a minimum.

Garnissage service – your screen re-garnished within 24 hours

We understand that screens are often critical components in a production process.

That is why Omnimesh offers an accelerated 24-hour garnissage service:

Your screen is re-garnished within 24 hours after receipt

Condition: the required screen mesh is available from stock

The screen must arrive at our facility before 10 a.m.

This allows us to minimize the impact on your production process and restore your operational efficiency as quickly as possible.

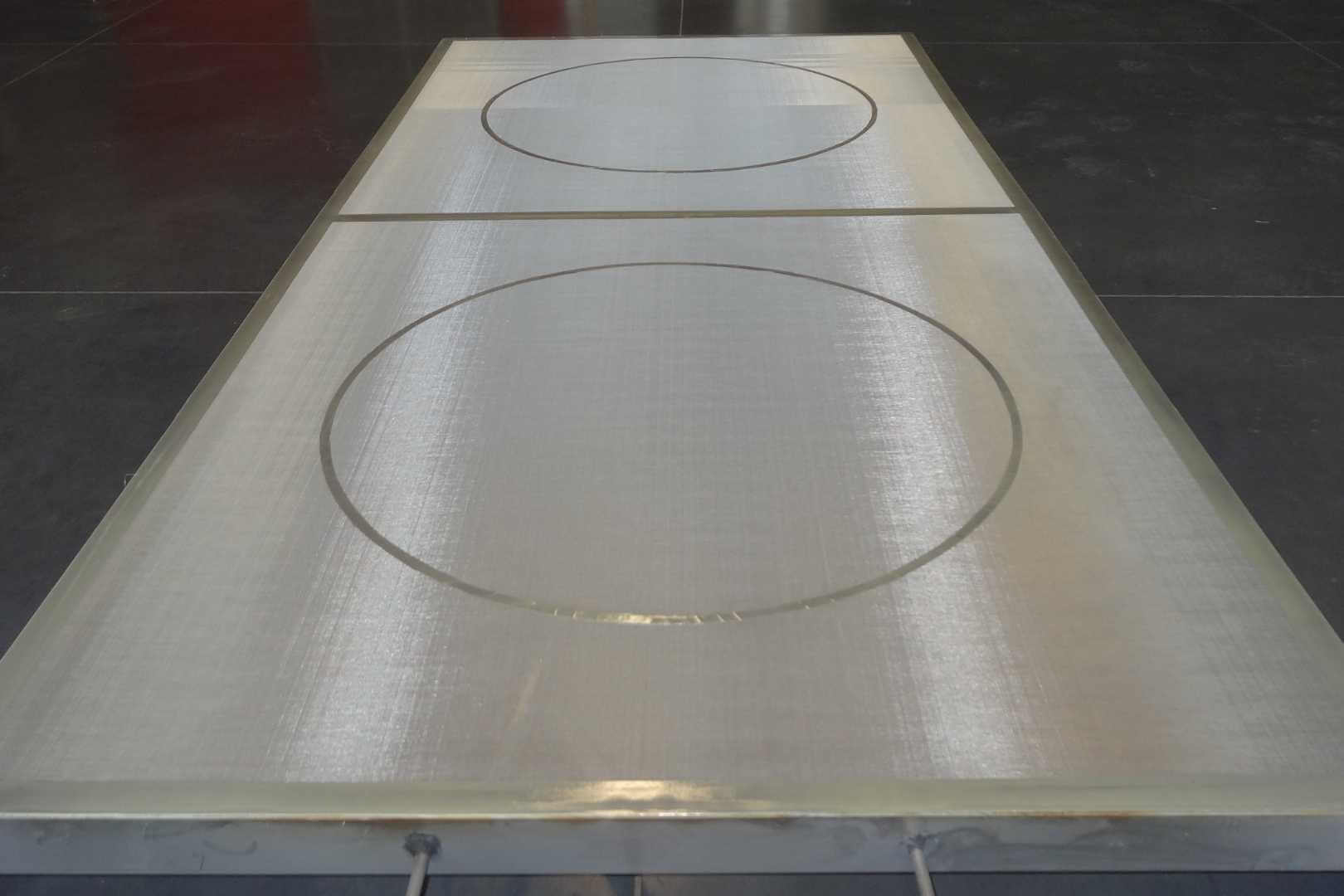

New custom-made screen frames and screen rings

In addition to re-garnissage, Omnimesh also supplies new screen frames and screen rings, fully aligned with the original design or custom-made for your application.

Options:

Round, rectangular, and square frames

Compatible with all brands and types of screening machines

Dimensions up to 3000 mm

Materials: steel, stainless steel (304/316), and aluminum

New frames are delivered with properly tensioned screen mesh, ready for immediate use.

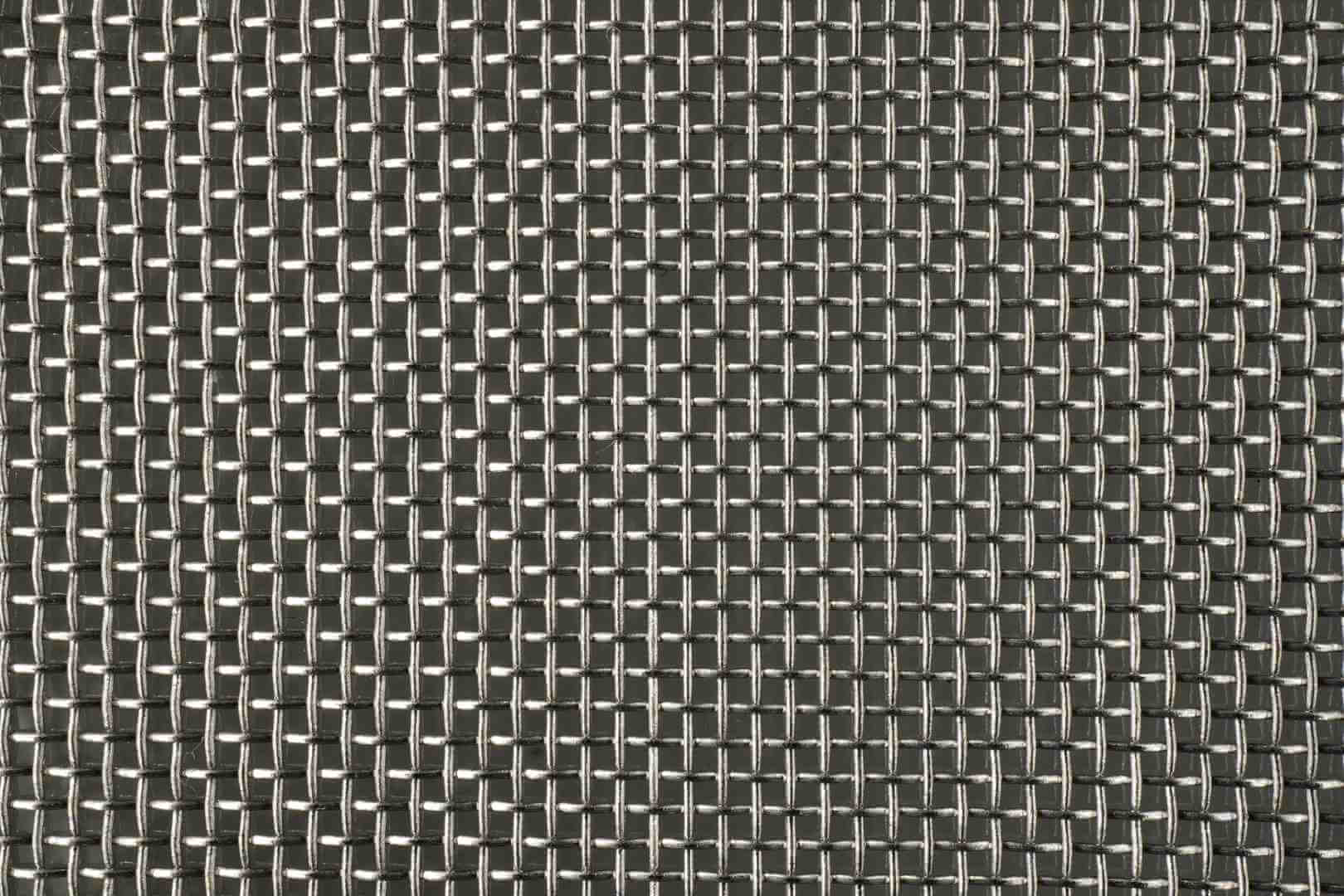

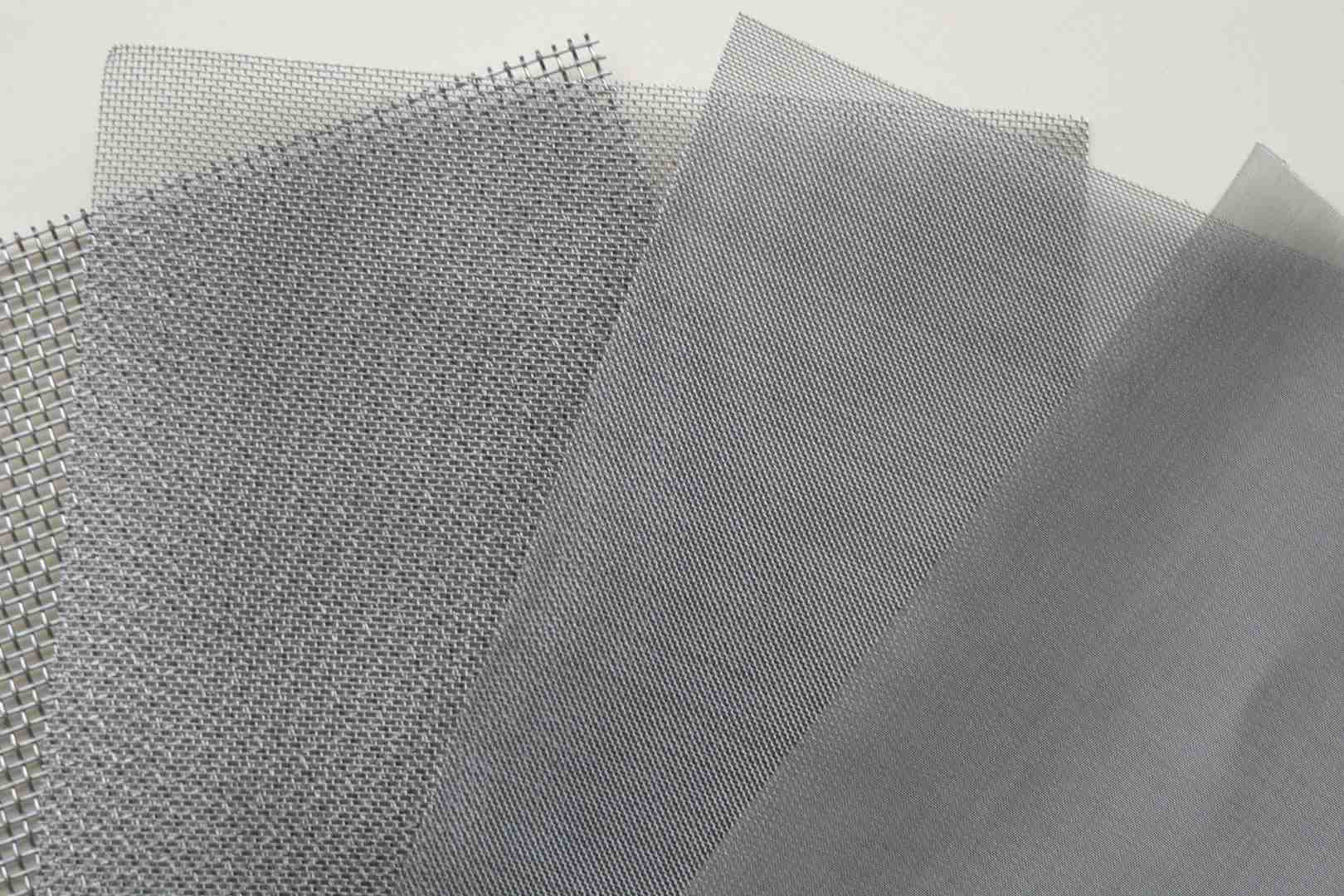

Materials for screen (re-)garnissage

As a metal mesh manufacturer, we maintain an extensive and permanent stock of woven metal mesh and filter mesh. This allows us to re-garnish screen frames very quickly, fully in-house. We work exclusively with metal mesh types.

Materials

Depending on the application, we process among others:

Stainless steel 304 – for general industrial applications

Stainless steel 316 / 316L – for corrosive environments and food and chemical processes

Spring steel – for high elasticity and mechanical load capacity

Alloys on request – such as Monel, Hastelloy, Inconel, … for specific chemical, thermal, or wear-resistant applications

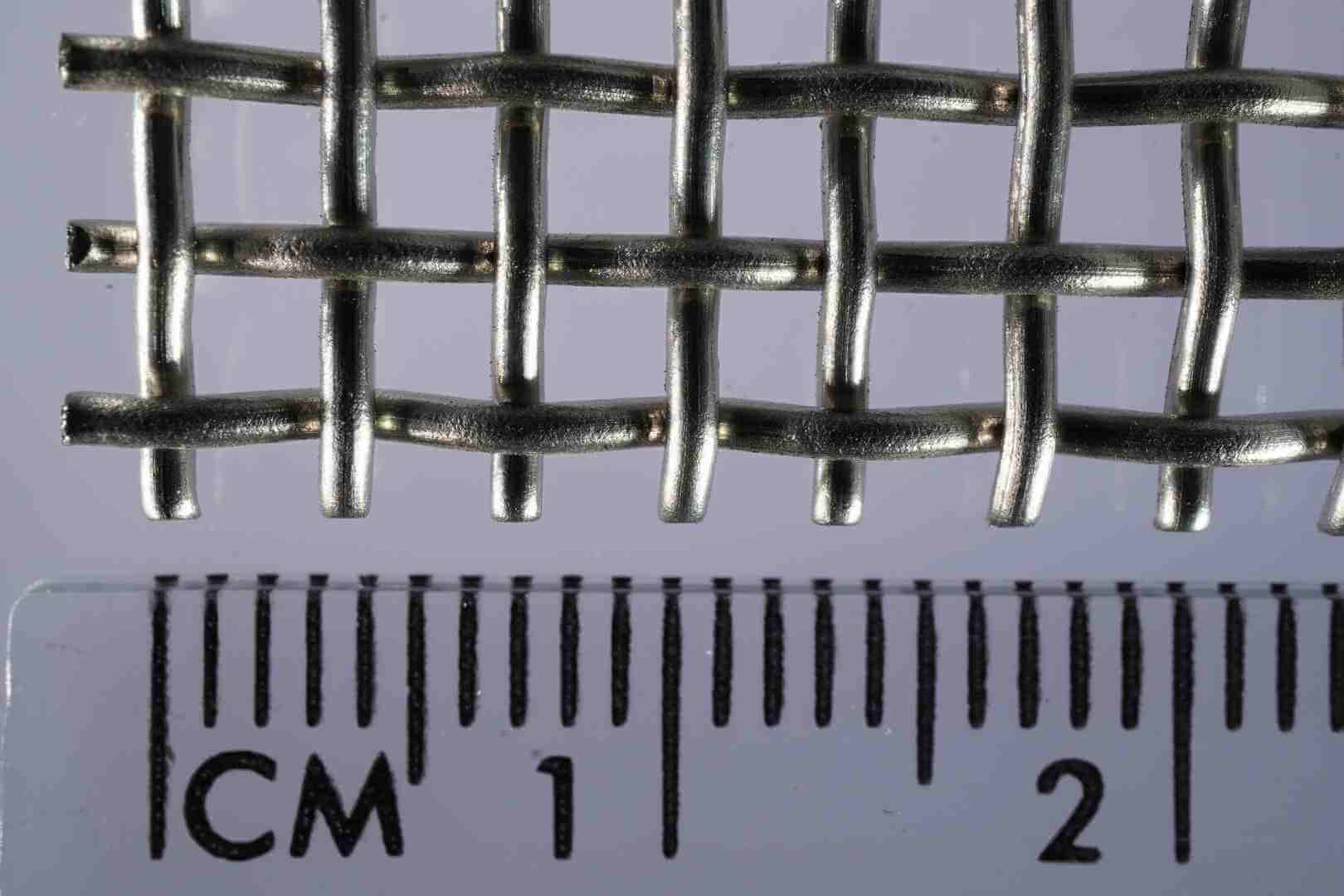

Mesh types

We re-garnish screen frames using various types of screen mesh or filter mesh, including:

Plain woven mesh

Twill weave

Dutch weave

Spot-welded mesh

Woven / braided mesh

The selection of material, weave type, and mesh size is always tailored to:

the product to be screened

the process and operating conditions

the required filtration fineness and throughput

the mechanical and dynamic load on the screen

Thanks to our in-house production, technical expertise, and large stock, we guarantee fast, reliable, and technically correct screen garnissage.

Price and costs of (re-)garnissage of industrial screen frames and screen rings

The price of screen garnissage or re-garnissage depends on several technical and practical factors.

Since each industrial screen frame or screen ring has specific requirements regarding tension, filtration fineness, and material selection, screen garnissage is almost always carried out on a custom basis tailored to the application.

The costs of (re-)garnishing a screen frame are determined, among others, by:

the type and dimensions of the screen frame or screen ring

the selected screen mesh (material, mesh size, and wire diameter)

the required tension and tolerances for the specific screening or filtration process

the condition of the existing frame (any required repairs or straightening)

the bonding and sealing techniques required for durable industrial fixation

Compared to purchasing a completely new screen frame, re-garnissage is generally significantly more cost-effective, while restoring the required throughput, separation quality, and process reliability.

At Omnimesh, you always receive a clear and transparent price indication for screen garnissage, tailored to your industrial application, with a focus on long service life, minimal downtime, and optimal operation of your installation.

Why choose Omnimesh?

Advantages of our screen garnissage service:

Specialization in industrial screen garnissage and re-garnissage

In-house production of screen mesh → fast availability

24-hour garnissage service possible in case of downtime

Technically correct tension and filtration fineness

Suitable for heavy industrial applications

Experience with all types of screens and screening machines

With Omnimesh, you choose reliable screen garnissage that supports your production process rather than slowing it down.

Industrial filter repair service — tailored to your process

From filtration and separation to industrial applications and custom projects: we support you with filter repair and professional screen garnissage for industrial processes.