Professional repair service for industrial filters and screens

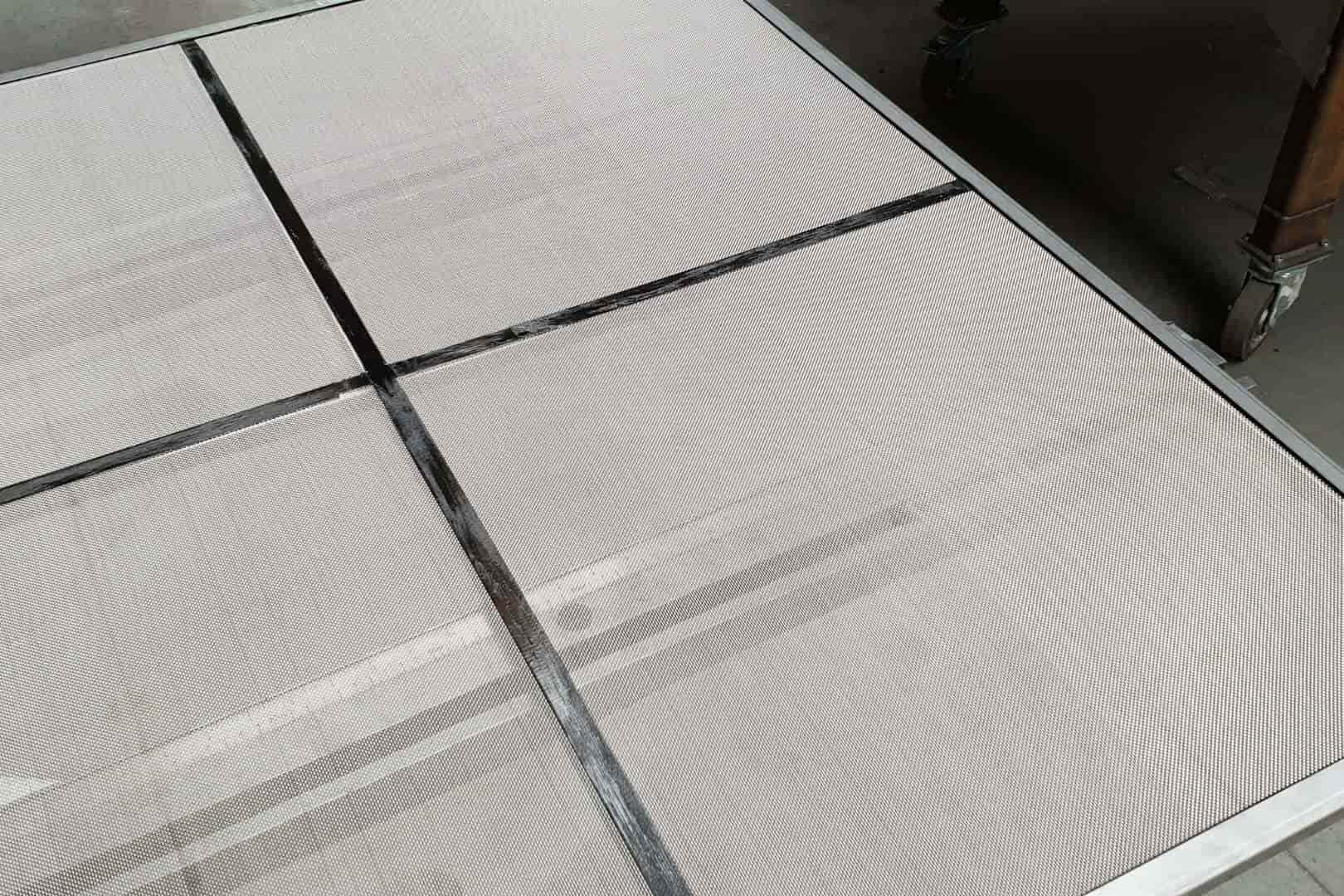

Repair and refurbishment of industrial filters for industrial and process installations

Urgent repairs in case of production downtime

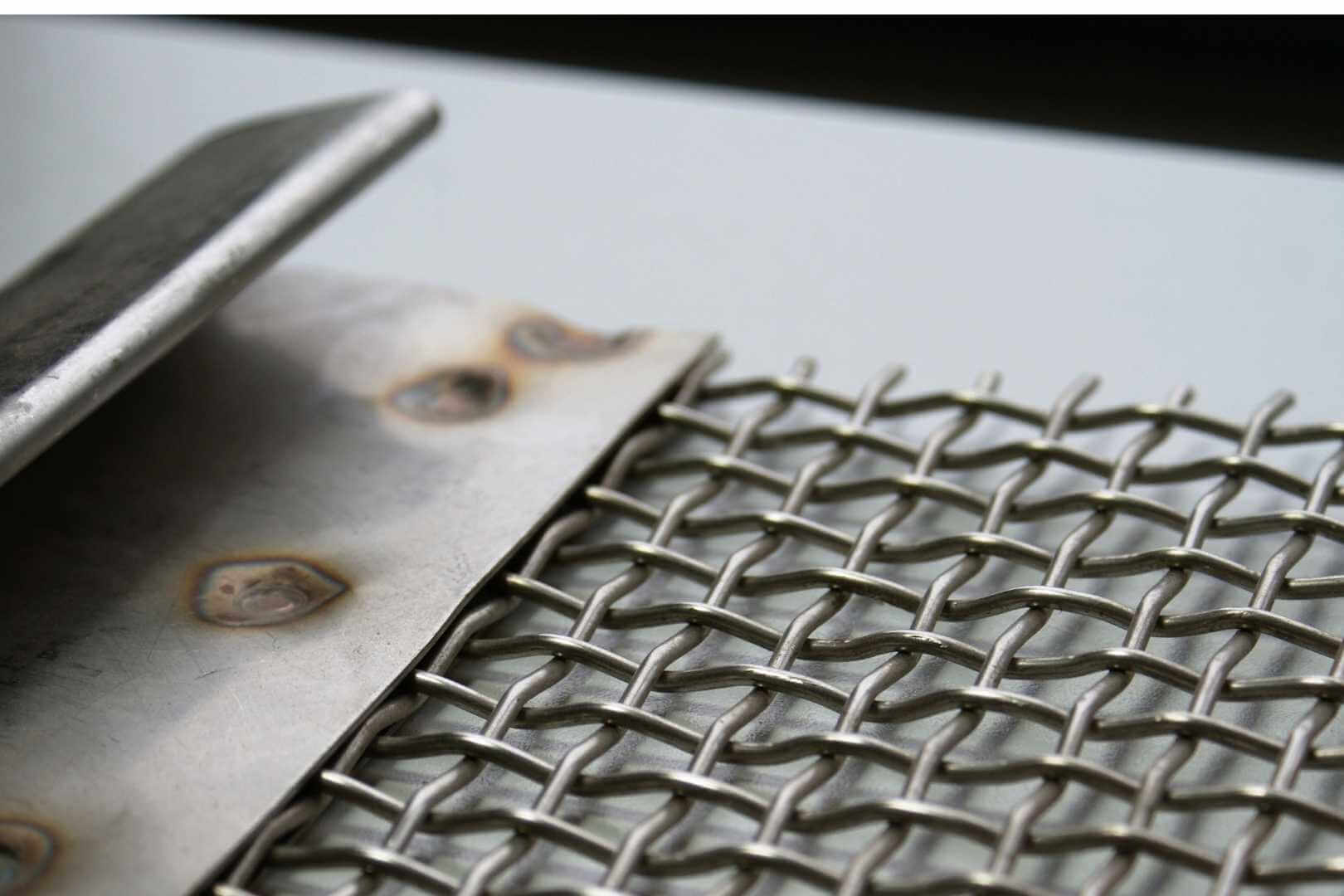

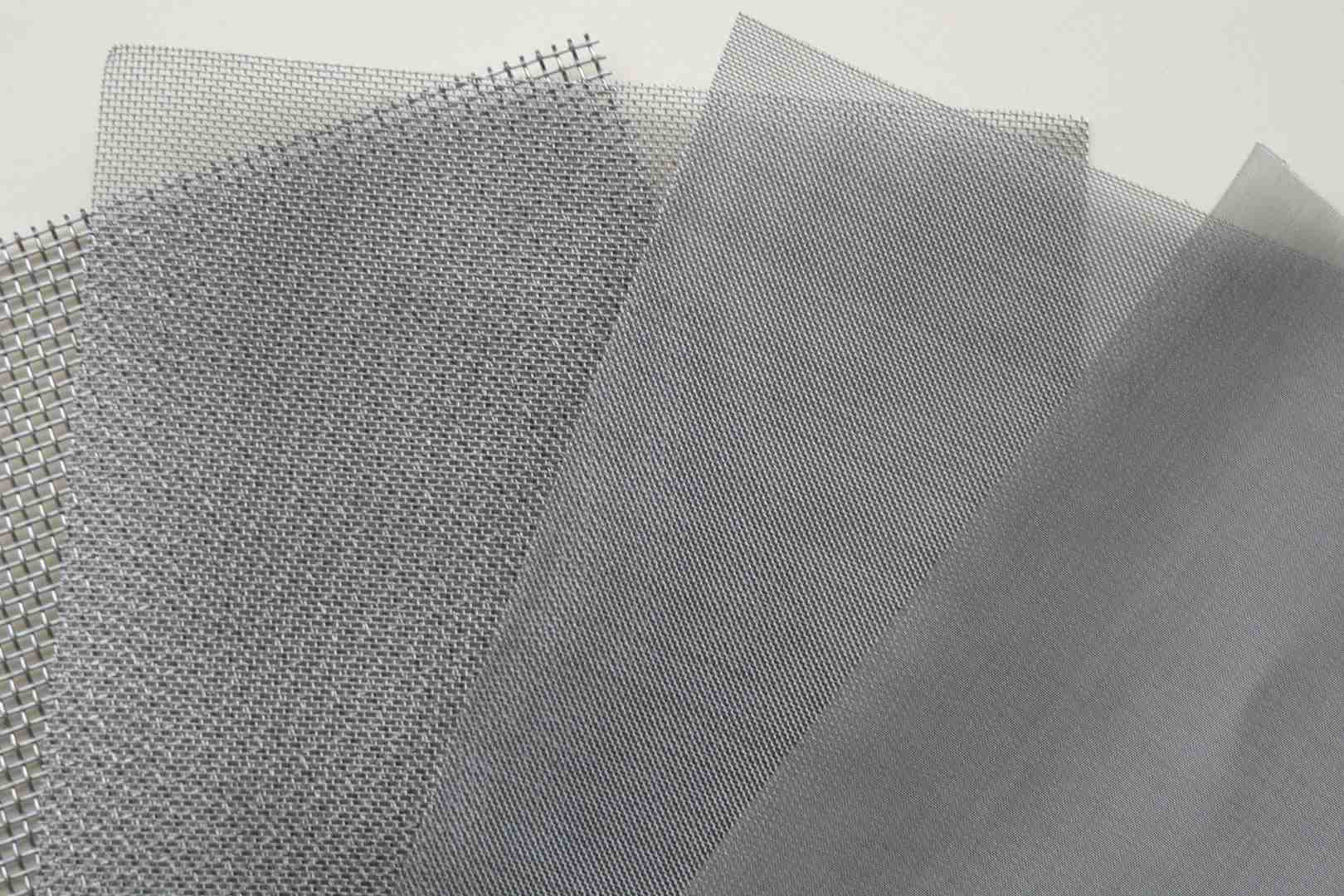

In-house production of wire mesh with extensive material stock

Technical advice for optimal filtration performance and service life

On this page:

Omnimesh specializes in the repair, refurbishment, and recommissioning of industrial metal filter elements.

From our in-house technical workshop, we support manufacturing and process companies in minimizing downtime and extending the service life of their filters.

Which industrial filter elements do we repair and refurbish?

Omnimesh has the expertise and infrastructure to restore a wide range of metal filter elements to a reliable and safe operating condition, regardless of brand, type, or the age of the installation.

Common filter elements we repair include:

→ Filter baskets and filter strainers

→ Drum screens and vibrating screens

→ Y strainers and inline filters

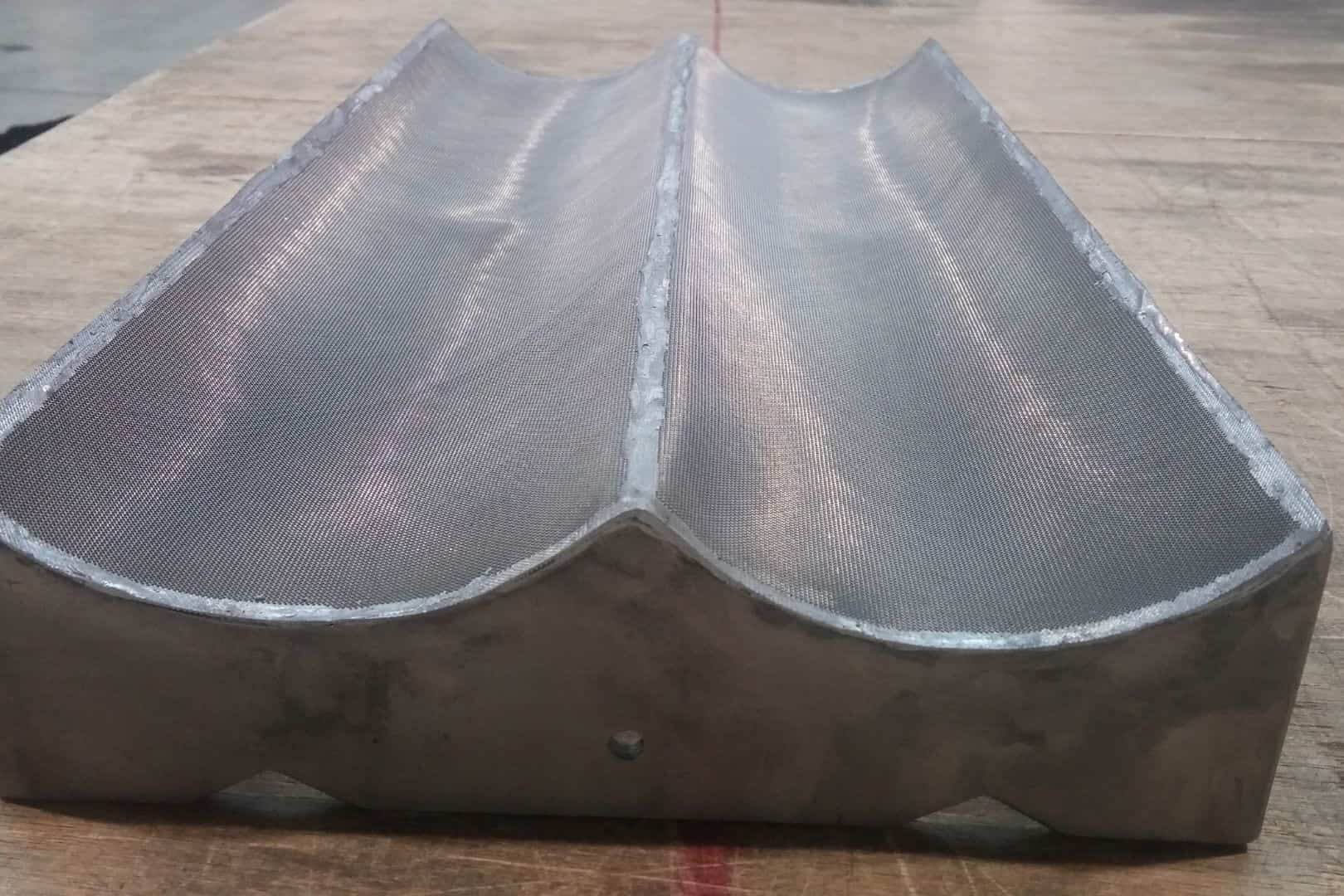

→ Conical filters

→ Screen decks and sieve rings

→ Filter cylinders

→ Custom-made filters and legacy installations

Screening and rescreening of sieve rings

Omnimesh offers a dedicated service for the screening and rescreening of sieve rings, focused on correct screen tension, accurate filtration fineness, and reliable operation of your installation.

In case of urgent production downtime, 24-hour service is available for rapid intervention.

When repair is not technically feasible or economically unjustified, we produce a new custom-made filter element or filter basket, fully tailored to your installation.

Which types of damage to metal filter elements can be repaired?

Industrial filters are continuously exposed to mechanical, chemical, and thermal stress.

As a result, damage may occur that reduces filtration quality or leads to unplanned downtime. Timely inspection and repair are therefore essential.

We repair, among others:

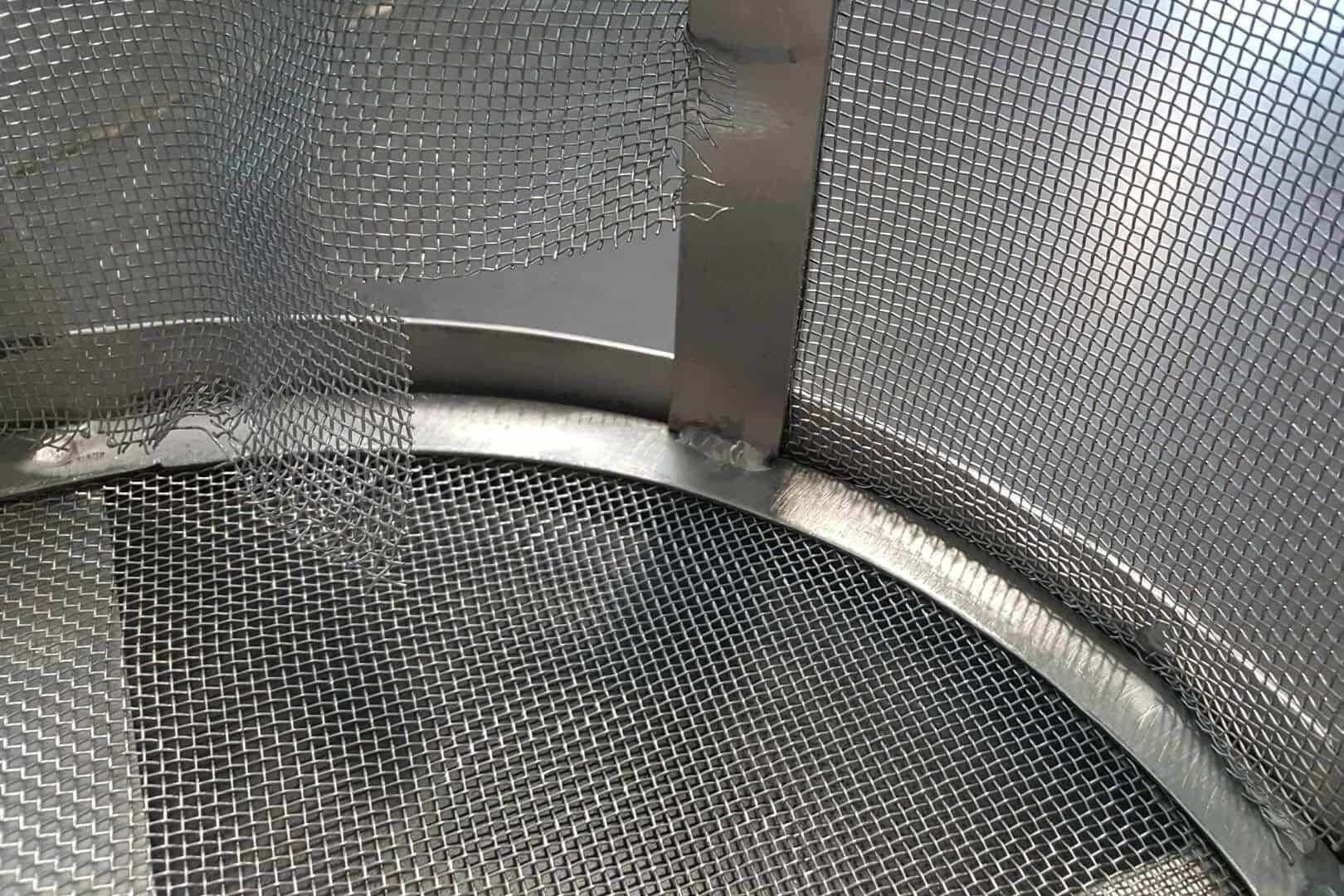

-> Gescheurde filterelementen en filtergaas

→ Deformed filter baskets or filter strainers

→ Corroded filter elements

→ Clogged metal filters and screen frames

→ Weld failures in filter frames

→ Wear on vibrating screens, drum screens, and conical filters

→ Modification or refurbishment of legacy or custom-made filters

How does the repair process of metal filter elements proceed?

Step-by-step overview:

Inspection of the filter for deformation, tears, holes, or clogging

Thorough cleaning of the filter element

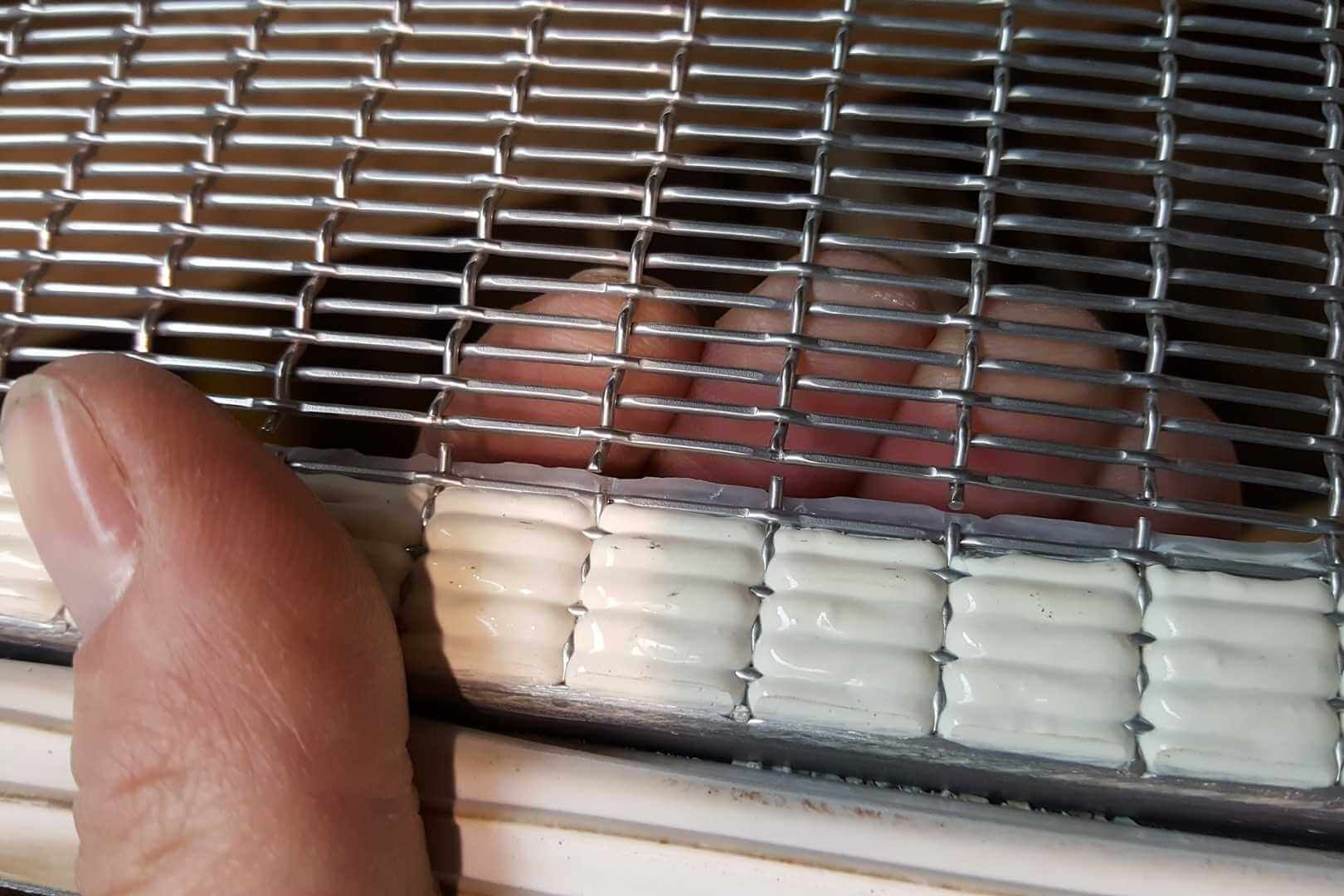

Repair or rewelding of the frame where needed

Rescreening with new wire mesh or perforated plate, matched to the required filtration fineness

Final check of flow performance and mechanical stability before reinstallation

Thanks to this structured approach, Omnimesh ensures durable repairs while maintaining filtration quality and minimizing impact on your production process.

Price and costs of repairing metal filters

A frequently asked question is: what is the cost of repairing metal filter elements?

In most cases, repairing metal filters is significantly more cost-effective than full replacement, especially when one or more of the following conditions are met:

the filter frame is still structurally intact

only the filter mesh is damaged or clogged

rapid repair is required to limit production downtime

The cost of repairing metal filter elements depends on several parameters, including:

the dimensions of the filter

the required filtration fineness

the material of the filter element

the complexity of the filter element

For this reason, Omnimesh always works with a tailored quotation, providing you in advance with a clear and accurate cost estimate, fully aligned with your filter and application.

Purchase metal mesh for self-repairing your filter

In addition to repair services, Omnimesh also offers the possibility to purchase custom-cut metal mesh for self-repair of filter elements. This option is ideal when you wish to carry out filter repairs in-house and want to be certain of using the correct filtration material.

Required information for a quotation:

Dimensions of the filter or screen frame (diameter, height, inner and outer dimensions)

Filtration fineness (micron or mm)

Material (stainless steel 304 / 316 or other alloys)

Quantity and application (chemical, food, petrochemical, etc.)

Photo or drawing of the existing filter element

The more complete the information provided, the faster we can prepare a targeted quotation and the more efficiently your in-house filter repair can be carried out.

Why choose Omnimesh?

Advantages of our repair service:

Specialized in the repair of metal filter elements and industrial screens

Fast and cost-efficient, with minimal production downtime

In-house production and extensive metal mesh stock, enabling rapid delivery

Technical advice for optimal filtration fineness and extended service life

Capability to refurbish all types of industrial filters, including filter baskets, strainers, drum screens, vibrating screens, filter cylinders, conical filters, and custom-made units

With Omnimesh, you are assured of a reliable, durable, and technically sound filtration solution.

Industrial filter repair service — tailored to your process

From filtration and separation to industrial applications and custom projects, we support you with industrial filter repair and professional screen tensioning for industrial processes.